Custom Solutions

Space, science and industrial applications

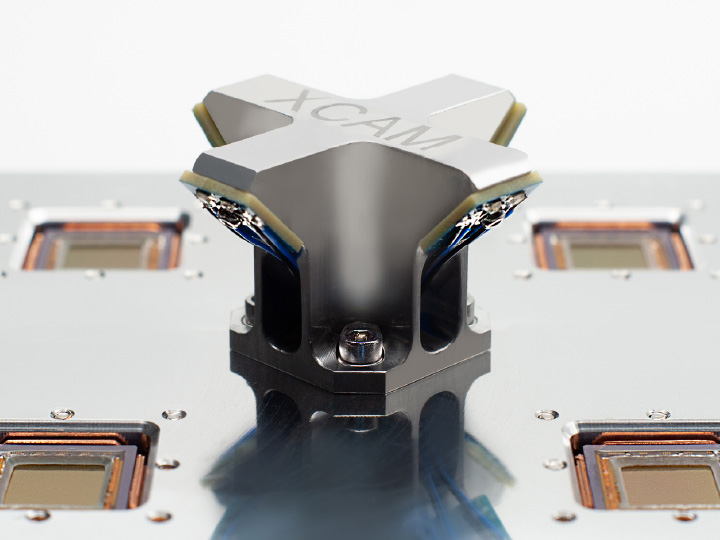

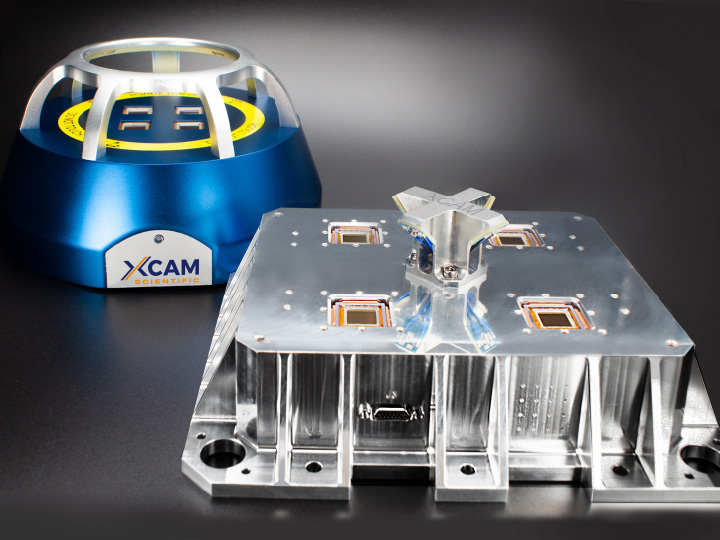

Camera Subassemblies

Components for customised systems

Space, science and industrial applications

Components for customised systems

Effective contamination control is essential for the success of high-tech manufacturing, assembly and operational environments.

The presence of contamination can have severe detrimental impacts on products, not only during manufacturing processes but also in their operational performance. Particulate contamination can cause a number of issues including component failure, adverse changes in optical properties, noise on electrical contacts, short circuits, and mechanical damages.

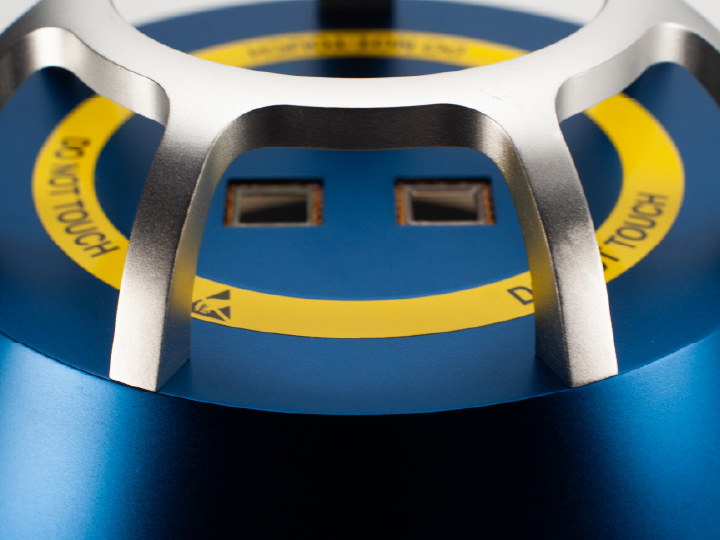

XCAM Scientific’s space Particle Fallout Monitoring (PFO) products are being developed initially as part of the European Space Agency (ESA) Technology Development Element (TDE) programme. An innovative source of real-time PFO data utilising digital imaging technology, they enable the autonomous monitoring of PFO in a multitude of environments and applications.

Real-time surface particulate monitoring for clean environments.

Whilst airborne sensing is ideal for small particles which remain suspended in the air and are removed by filtration, the higher risk to operations can be from particles larger than 5 μm, which are more quickly deposited on surfaces leading to contamination and yield losses.

XCAM Scientific’s PFO 1040 provides continuous, real-time particle monitoring and analytics, enabling users to detect contamination events and observe fallout trends as they develop. By removing the need for physical sample retrieval, it significantly lowers both monitoring time and operational cost.

Particulate monitoring for space launch applications.

Launch vehicles, and their enclosed satellite payloads, experience significant mechanical and acoustic shock and vibration during their short journey to space. Nothing is currently known about the sources and types of particulate contamination inside a rocket fairing during launch; however it is certain that contamination can seriously affect performance, accuracy and reliability of the multi-million dollar instruments which are routinely sent into space to study our planet and explore the universe.

XCAM Scientific has been leading a technology development programme to provide the first measurements of particulate fallout during launch.

Monitoring particle fallout ensures that every stage of your manufacturing or assembly process remains free from contamination sources that can silently undermine quality.

The accumulation of particles on surfaces, particularly those greater than 5 µm that settle out of the air, can lead to optical degradation, scattering, electrical contact faults, mechanical damage or outright part failure.

By deploying real-time particle fallout monitoring, you gain early warning of contamination build-up, enabling intervention before defects occur, re-work is required, or entire batches are scrapped. In other words: keeping particle fallout in check protects your yield, lowers cost per good unit, and supports profitability.

Particle fallout is not a one-off event, it evolves with process activity, personnel movement, equipment status, maintenance cycles and even subtle environmental changes.

Real-time monitoring systems provide continuous data on fallout rate, size distribution, deposition patterns, and temporal trends, correlate with jumps in contamination levels. This trend-data becomes a powerful tool for root-cause analysis, process improvement, and predictive planning.

By understanding when, where, and why particles are settling out, workflows can be fine-tuned to schedule cleaning or maintenance - transforming contamination control from reactive to proactive - benchmarking performance improvements over time.

In highly demanding fields such as optics, semiconductors, and space, surface cleanliness is non-negotiable. Monitoring particle fallout is a key pillar of any robust quality assurance or product assurance programme.

It demonstrates that environments, equipment, and personnel are maintaining required cleanliness standards and that products are being built under controlled, compliant conditions.

By integrating particle fallout monitoring data into QA/PA records, there is documented evidence of environmental integrity, enabling compliance with clean-room and industry standards, strengthening audits, and giving customers confidence in process control. Ultimately, it helps ensure that the end-product meets its designed performance criteria, not just in the lab, but in real-world operation.

International Symposium on Contamination Control

International Symposium on Contamination Control

International Symposium on Contamination Control

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific is now part of Tibidabo Scientific IndustriesStrengthening our ability to deliver world-class imaging solutions for space, scientific, and industrial applications.