Custom Solutions

Space, science and industrial applications

Camera Subassemblies

Components for customised systems

Space, science and industrial applications

Components for customised systems

XCAM Scientific has been spearheading a technology development program, funded by the European Space Agency (ESA), to create a unique instrument for measuring particulate contamination inside a launch vehicle fairing during liftoff.

Central to the concept of operations, is the elimination of the need for tele-commanding between the launch vehicle (LV) and the instrument. When power is supplied to the unit, it automatically enters a pre-programmed power-up sequence before moving to a pre-flight data acquisition and transmission mode.

Using a combination of environmental sensors, the unit can autonomously detect when launch commences and move to the flight data acquisition and transmission mode, operating for a fixed duration between launch and fairing ejection. The unit then enters a post-flight transmission mode, transferring the remaining data to the launch vehicle for telemetry to the ground.

XCAM Scientific’s proprietary algorithms allow instant analysis of launch campaign data, detecting and classifying particles at any time.

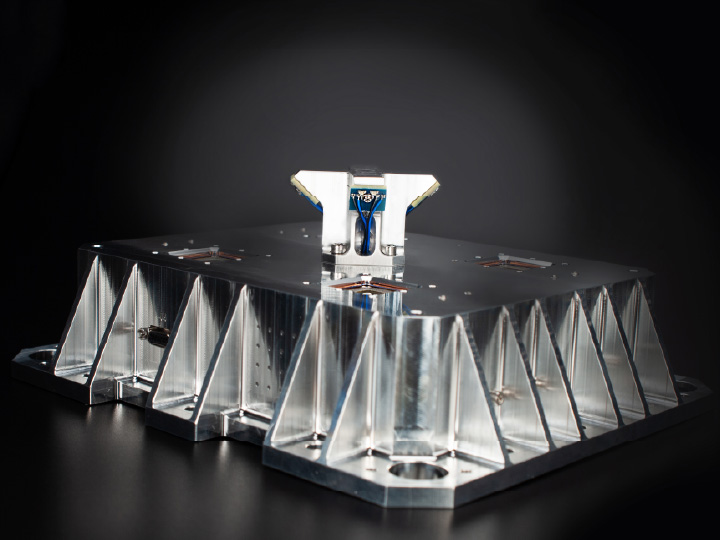

withstands the varying vibration, shock, acoustic, pressure, temperature, and humidity environments experienced during space launch.

enables deployment across a wide range of launch vehicles.

detecting and classifying particles and fibres every 10 s.

using a special chrome-on-glass test mask to confirm optimal operation.

the Space PFO is being considered for ESA’s Ariane-6 and Vega-C launch vehicles from 2027 launches onwards.

to meet the demands of your mission

Launch vehicles, and their enclosed satellite payloads, experience significant degrees of mechanical and acoustic shock and vibration during their journey into space.

Nothing is currently known about the sources and types of particulate contamination inside a rocket fairing during launch; however, it is certain that contamination can seriously affect the performance, accuracy and reliability of the multi-million dollar instruments which are routinely sent into space to study our planet and explore the universe.

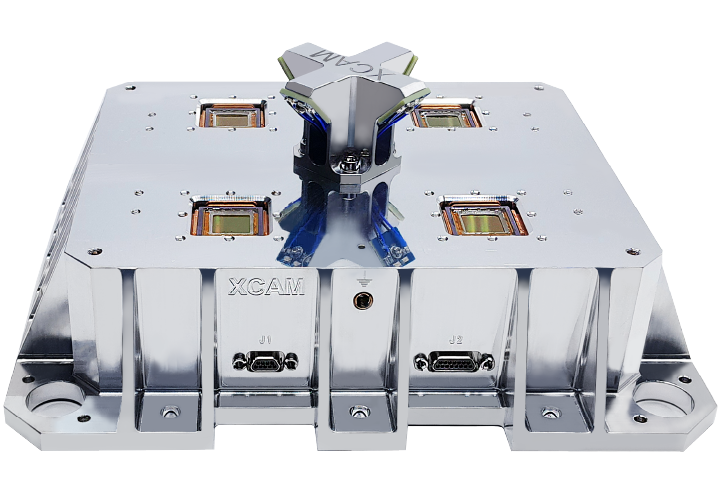

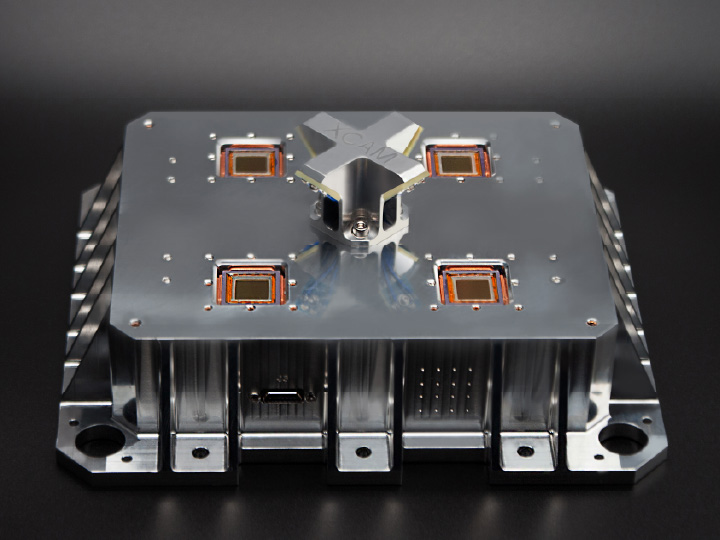

Space PFO engineering model

Space PFO flight ready unit

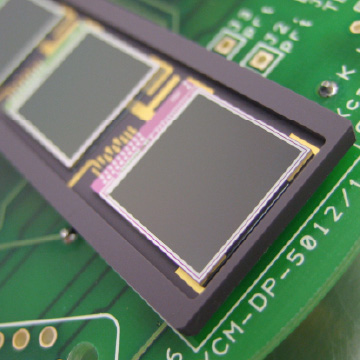

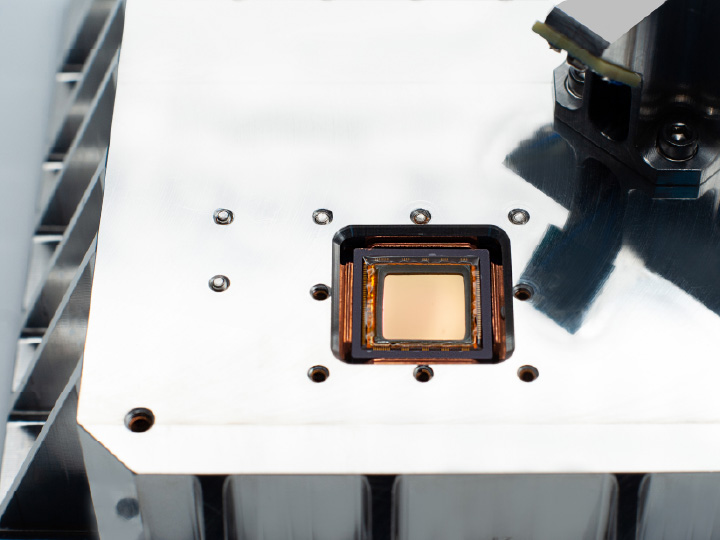

High performance sensors

The Space PFO is a real-time particle fallout (or deposition) monitor designed for space launch applications. It detects particles in the range from 5 um to >750 um that settle onto surfaces, rather than particles that remain airborne. Its purpose is to detect and quantify surface contamination risks that can seriously affect the performance, accuracy and reliability of multi-million dollar instruments which are routinely sent into space.

The Space PFO uses XCAM Scintefic’s Direct Particle Detection (DPD) technology, adapted for the extreme environment of space launch. It directly images particles as they settle onto a silicon imaging sensor. Using built-in illumination and high-resolution CMOS detectors, the system captures images of each deposited particle in real time. Advanced onboard algorithms then analyse these images to measure particle size, shape, and distribution. This approach provides the first direct, in-flight measurement of particulate fallout inside a rocket fairing, delivering real-time contamination data during launch and ascent.

The Space PFO autonomously collects and stores contamination data throughout the launch sequence. Each capture is time-stamped and includes particle count, size, shape, and classification information. Data is transmitted via telemetry, depending on mission configuration. The system provides quantitative particle fallout metrics that can be correlated with other environmental data, such as vibration and temperature, giving engineers a detailed picture of contamination events during launch. While the Space PFO does not issue live alarms like the ground-based version, it delivers comprehensive post-flight datasets and reports suitable for contamination-control analysis and mission verification.

During a rocket launch, vibrations, material shedding, and acoustic loads can release particles that settle on spacecraft surfaces. These contaminants can scatter light, obscure optics, or interfere with sensitive instruments. Particle fallout monitoring helps quantify how much particulate contamination actually reaches payload surfaces during flight, filling a long-standing knowledge gap in launch cleanliness. Insights from this data allow engineers to improve fairing design, material selection, and contamination-control protocols, ultimately protecting high-value payloads and ensuring mission success.

While both instruments use XCAM Scientific’s Direct Particle Detection (DPD) technology, the Space PFO is purpose-built for the harsh mechanical and thermal conditions of rocket launches. It is compact, ruggedised, and fully autonomous so it can operate without any external control during the entire launch sequence. The PFO 1040, by contrast, is designed for cleanroom and terrestrial environments, providing continuous contamination monitoring in controlled facilities. The Space PFO extends this proven technology beyond the lab, offering the first opportunity to measure and understand particle fallout directly inside a launch vehicle fairing, a critical step toward improving contamination control in space missions.

Contact our sales team for further details, a quotation, or to discuss development opportunities.

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific is now part of Tibidabo Scientific IndustriesStrengthening our ability to deliver world-class imaging solutions for space, scientific, and industrial applications.