Custom Solutions

Space, science and industrial applications

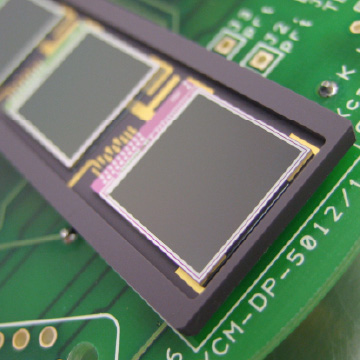

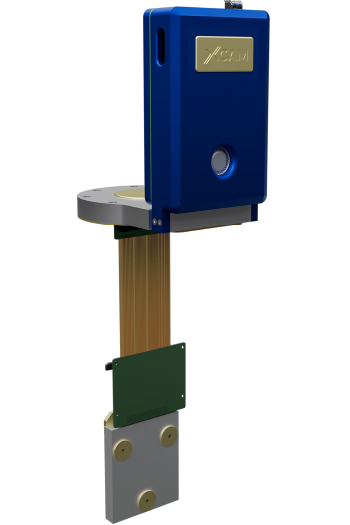

Camera Subassemblies

Components for customised systems

Space, science and industrial applications

Components for customised systems

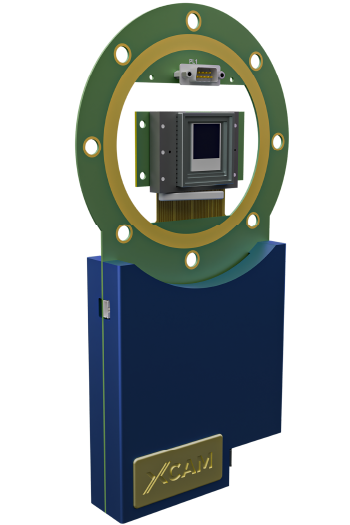

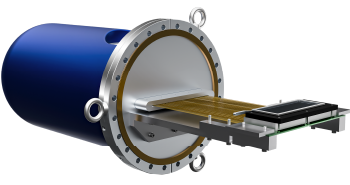

Multi-functional imager characterisation and testing systems offering plug-and-play operation for a wide range of testing conditions.

XCAM Scientific’s imager control systems are designed and built to operate a specific sensor model. Our advanced electronics power even the most challenging of sensors, enabling characterisation and testing of the sensor earlier in a project timeline, before full integration into the larger system.

Comprised of a main board, which can be used either in-air or in-vacuum, with the clever design of a low-outgassing section of the board which can be clamped between vacuum components.

2k x 2k back-illuminated sensor, 10 µm pixels, optimised for visible, UV, and EUV.

Image sensor combining TDI CCD functionality on a CMOS chip.

Easy operation of the CIS 300 family of sensors, up to 9k x 9k µm pixels.

High performance stitched SWIR detector for satellite instruments.

An Imager Control System (ICS) is the electronic interface that manages and operates an imaging sensor. It provides the precise power, current, and voltages required for the detector to function reliably, and allows the user to configure the sensor in any of its operating modes. The ICS also receives and processes all data output from the detector, converting it into a digital format and passing it to a connected PC, where it becomes available for display, analysis, or storage. In short, the Imager Control System is the bridge between the imaging device and the user’s computer.

Characterisation of a sensor is the process of performing detailed electro-optic and radiation testing to understand and optimise its performance. This involves measuring key parameters such as sensitivity, noise, gain, and response to light or radiation. During characterisation, users may need to finely adjust bias voltages or specific timing of signals to achieve the sensor’s best possible performance. The results provide a complete performance profile, ensuring the sensor operates at peak efficiency for its intended application.

Yes- all our designs allow the user to position inside the vacuum chamber for cooled operation.

To operate an Imager Control System, a DC power supply to provide stable power to the unit and a PC equipped with a National Instruments (NI) data acquisition card is required.

Because imaging sensors are highly complex and can operate in many different modes, we recommend that you contact XCAM Scientific directly to discuss your specific requirements. Since each sensor mode may have unique characteristics, liaising with our engineering team allows us to verify optimal performance for your intended application and, if necessary, perform additional testing.

Contact our sales team for further details of existing imager control systems, or to discuss a new sensor-specific design.

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific is now part of Tibidabo Scientific IndustriesStrengthening our ability to deliver world-class imaging solutions for space, scientific, and industrial applications.