Custom Solutions

Space, science and industrial applications

Camera Subassemblies

Components for customised systems

Space, science and industrial applications

Components for customised systems

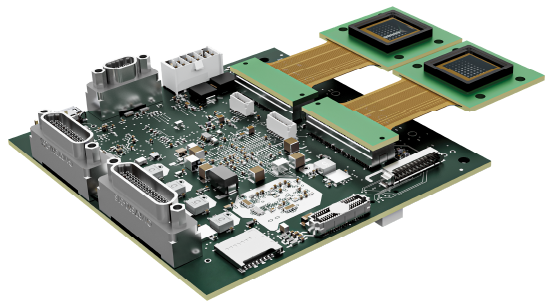

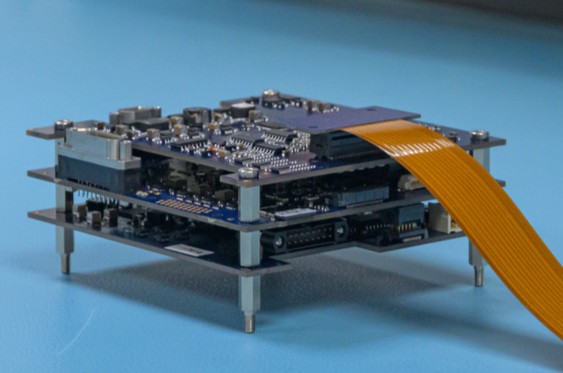

Modular subassemblies are used to manufacture our systems; enabling us to select the most appropriate elements with which to build customised systems at a relatively low cost.

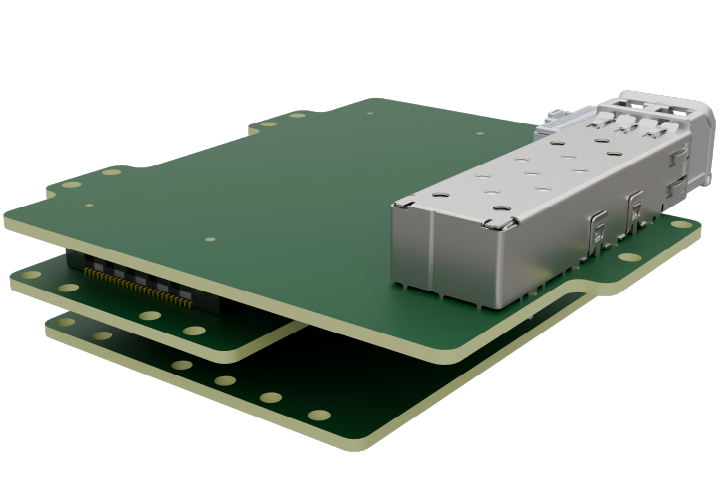

These include CCD, sCMOS, and Machine Vision CMOS Drive Electronics, Fibre Optic Transceivers, and a range of power supply units and temperature controller systems built to different specifications.

Additional examples of our modular electronics include Low-Outgassing Fibre Optic Cables, Camera Link Cables, and USB cables designed specifically for contamination sensitive in-vacuum applications, to name a few.

By using these tried-and-tested building blocks, we can create customised imaging systems efficiently and cost-effectively, while maintaining the highest standards of quality and performance.

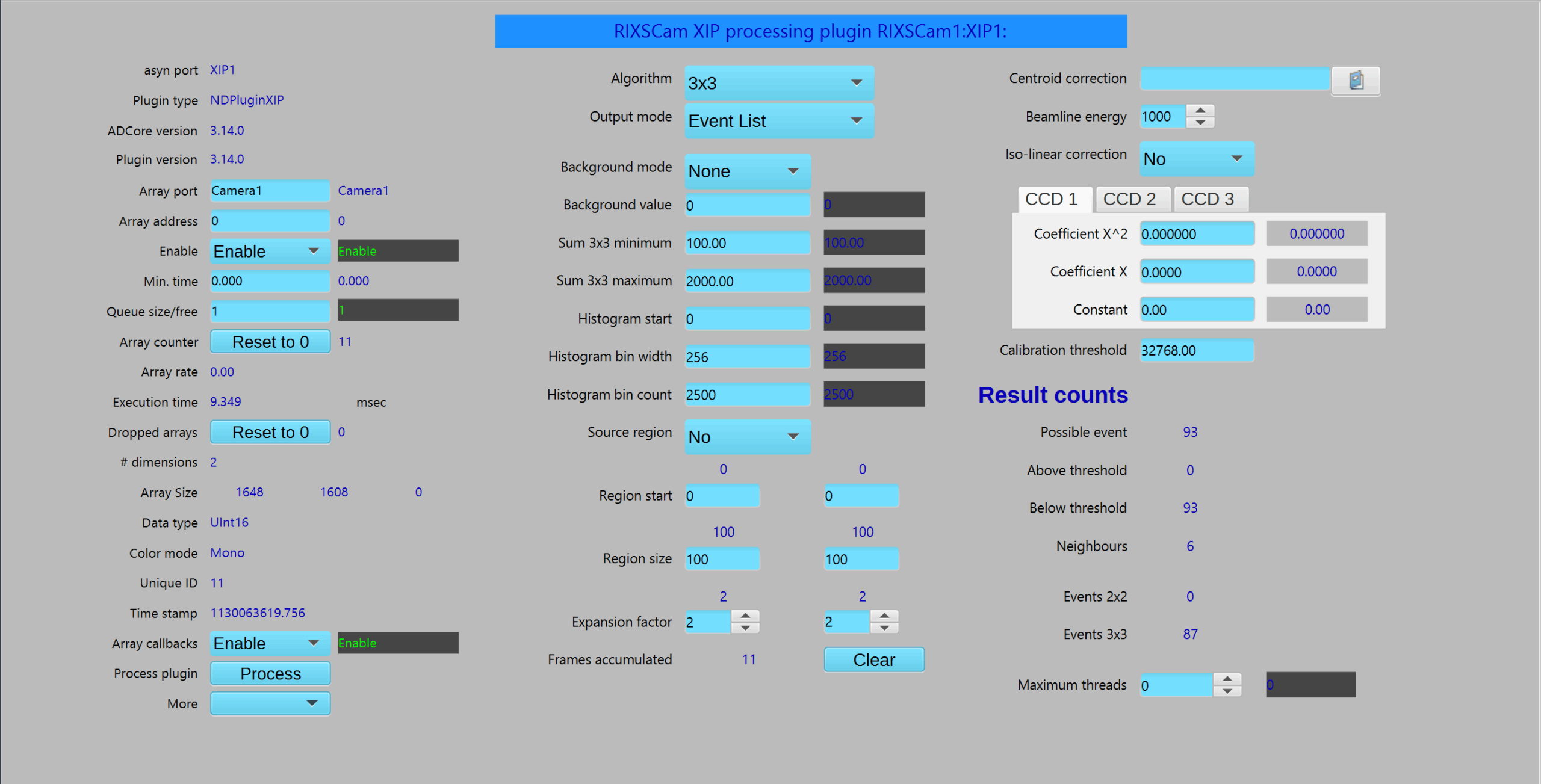

XCAM Scientific offers a range of control systems which can be configured to drive all commercially available detectors.

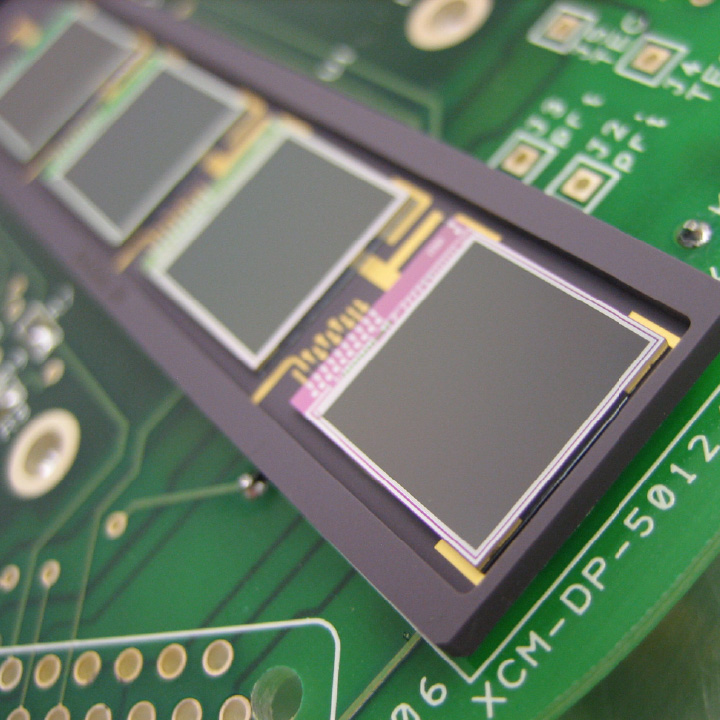

From large format for RIXSCam to small format camera head electronics for multiple CCD types, our electronics enable the close-butted array of detectors for synchronous operation.

NuSCIS electronics are cost effective for Engineering Model format in lab use and can drive a wide range of detectors.

Designed for clean, stable, and precisely regulated output, these power supply units support a wide range of detector systems. They provide low-noise, reliable performance for both laboratory and in-vacuum imaging applications.

Our temperature control modules provide accurate, low-noise thermal regulation for sensitive detectors. With excellent stability, they maintain optimal operating conditions to ensure consistent performance and high-quality imaging results.

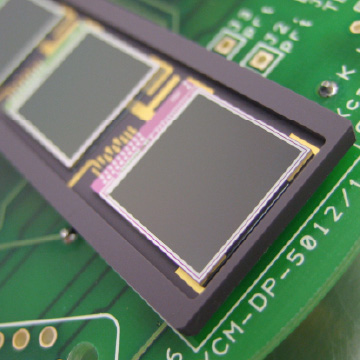

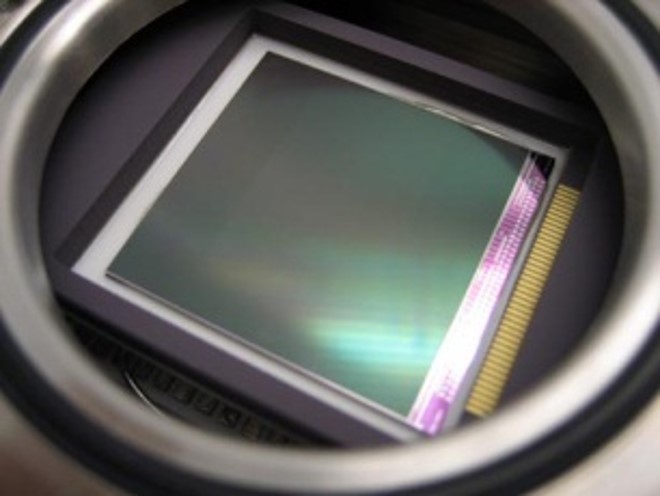

This ensures the correct detector pins are connected to the correct controller function while handling preamplication.

Detector headboards are dependant on the controller used.

For signal transfer to the headboard, and data return to the controller.

Additional cables for temperature monitoring and control are also available.

Including camera heads that are used in our standard products, as well as custom-made with specific requirements.

Windows-based software enables you to operate the camera system and get up and running quickly.

By using pre-designed and thoroughly validated subassemblies, we minimise risk, reduce lead times, and limit cost. These proven components provide a reliable foundation for your customised imaging system, ensuring consistent performance while streamlining development and integration.

Using electronics that are already designed and proven significantly accelerates the development process, taking your imaging system from concept to delivery faster and more efficiently.

Using existing subassemblies means you only pay for additional parts and testing specifically required for your customised system, avoiding the expense of redesigning or recreating components that already exist. This approach delivers maximum value without compromising quality.

Our engineering team is ready to advise and design your custom camera from our range of tried and tested components.

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific is now part of Tibidabo Scientific IndustriesStrengthening our ability to deliver world-class imaging solutions for space, scientific, and industrial applications.