Custom Solutions

Space, science and industrial applications

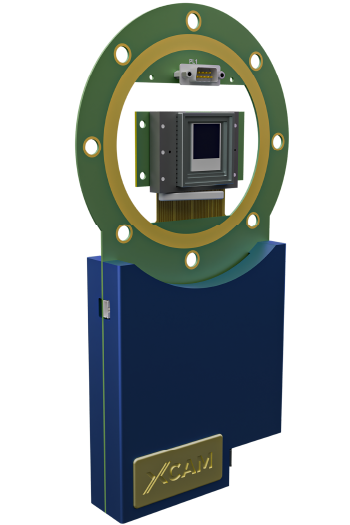

Camera Subassemblies

Components for customised systems

Space, science and industrial applications

Components for customised systems

From assembly to evaluation and testing.

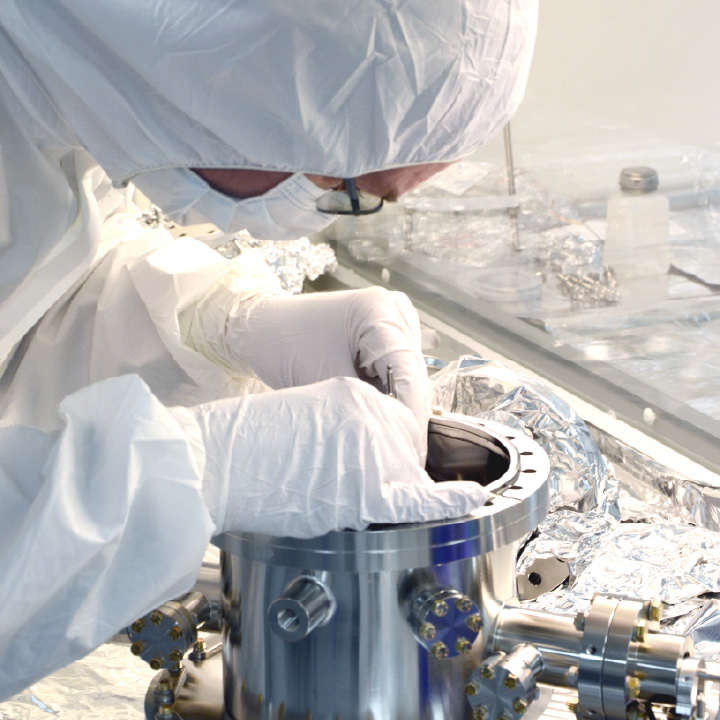

From assembly and integration to pre-launch testing, every spacecraft depends on precise, reliable ground support equipment (GSE). XCAM Scientific designs and delivers advanced GSE solutions that ensure instruments, satellites, and launch systems are accurately tested, calibrated, and ready for mission. Our rugged, configurable equipment helps mission teams streamline workflows, maintain strict quality standards, and reduce risk, so every launch starts with confidence.

XCAM Scientific provides ground systems engineered to perform under the same demanding standards as the missions they support.

From detector evaluation and optics testing – to monitoring clean room environments for optimal assembly conditions, XCAM Scientific’s advanced imaging and detector technologies support space missions from the ground up.

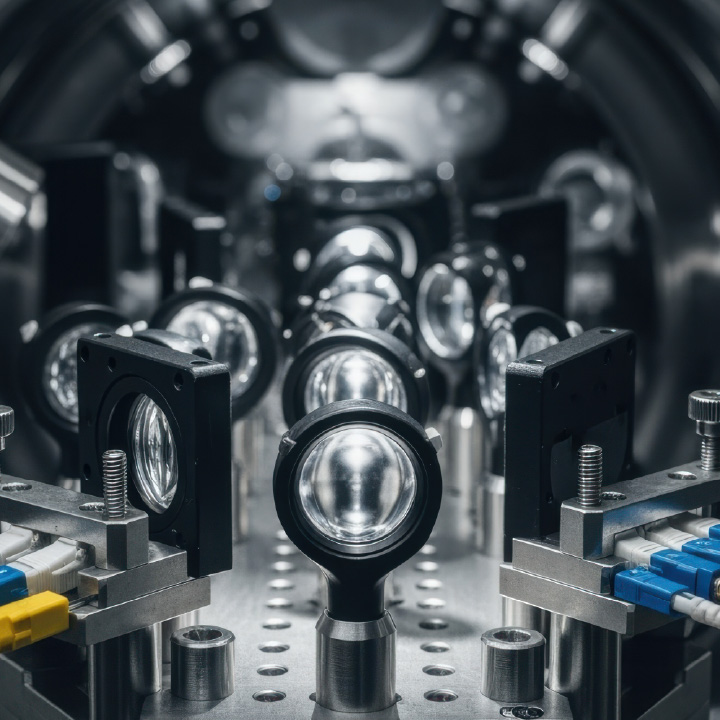

Low-outgassing GSE imaging solutions provide high-resolution and low-noise measurements for ground-based space optics testing, enabling accurate calibration, alignment verification, and performance assessment of optical systems before launch.

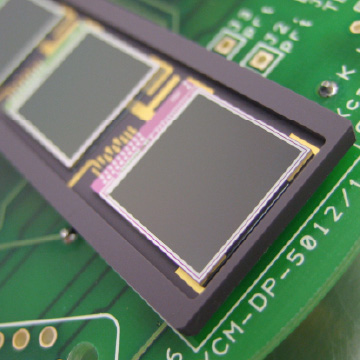

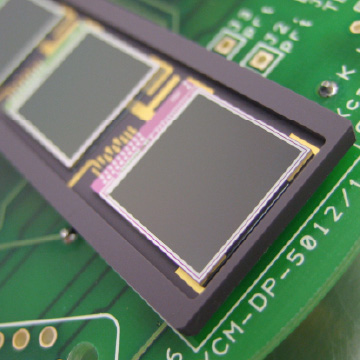

Detector evaluation kits enable space scientists to evaluate detector performance with high precision, capturing detailed response, sensitivity, and noise characteristics, ensuring reliable operation of imaging sensors in demanding space environments. They also enable radiation testing to confirm that detectors can endure the intense radiation encountered in space.

Particle fallout monitoring solutions in clean rooms- provide high-resolution, real-time imaging to detect and quantify contaminant particles, ensuring stringent cleanliness standards for various sectors including aerospace and semiconductor manufacturing.

Designed and manufactured to space-grade standards, GSE imaging solutions provide precise visual inspection, alignment verification, and defect detection, ensuring components meet stringent quality, cleanliness, and performance requirements for space missions. Every material is tested for outgassing and fully documented with an ECSS- compliant material list.

Real-time surface particulate monitor and analyser for clean environments to identify and track contamination incidents as they occur.

Imager control systems designed and built to operate specific sensor models to enable characterisation and testing early in a project timeline.

XCAM Scientific’s expert team is ready to support your mission from the ground up – ask for more details.

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific is now part of Tibidabo Scientific IndustriesStrengthening our ability to deliver world-class imaging solutions for space, scientific, and industrial applications.