Custom Solutions

Space, science and industrial applications

Camera Subassemblies

Components for customised systems

Space, science and industrial applications

Components for customised systems

Real-time particle monitoring and analysis allow continuous tracking of fallout trends, immediate detection of contamination events, and streamlined operations by eliminating the need for manual sample collection, reducing both time and operational costs.

PFO 1040 uses high performance silicon sensing to directly observe particles settling on the surface of the sensor. Advanced recognition algorithms detect particle size and profile, particle count by size, percentage area covered, and a differentiation between fibres and particles. Alarms can be triggered when pre-defined limits are exceeded.

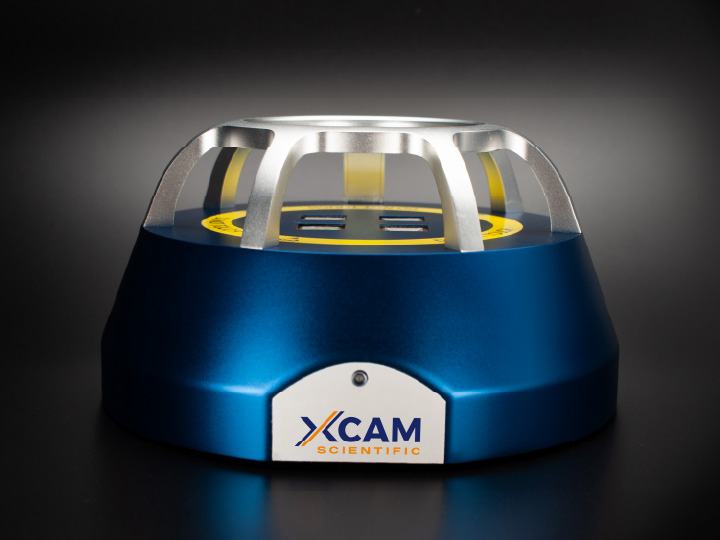

XCAM Scientific’s PFO 1040 model utilises all four sensors simultaneously to maximise sample area and the statistical significance or your results.

allows continuous tracking with time and room activity.

with particle image display and software analysis for particle and fibre classification.

compliments airborne sensing systems that only detect smaller particles that remain suspended in the air.

enables earlier action to limit contamination and avoid yield losses.

to meet cleanliness levels required for contamination-critical products and processes.

with reporting dashboard for ease-of-use.

PFO 1040

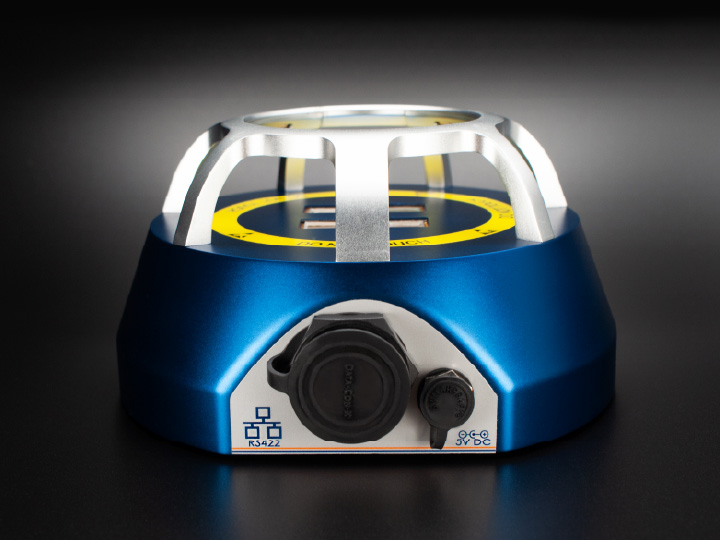

Connection panel

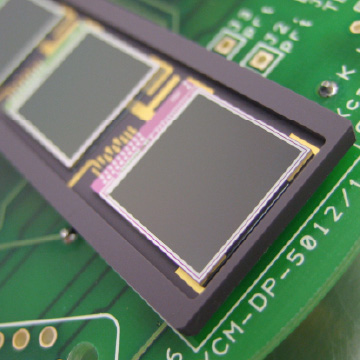

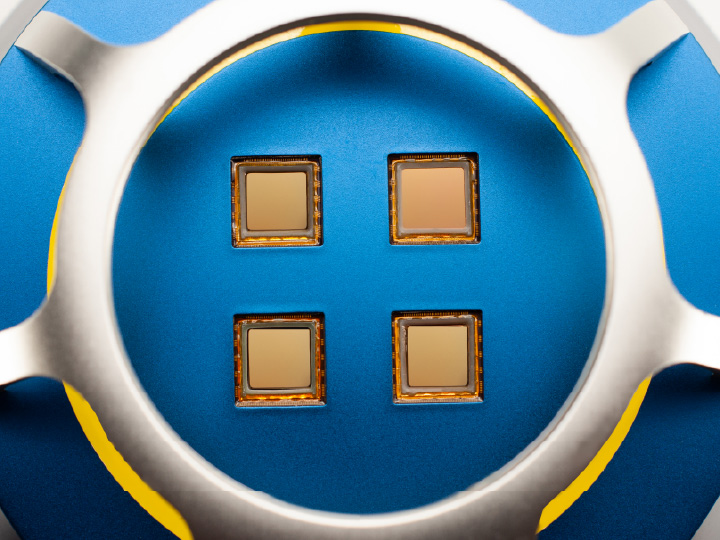

Four high performance sensors

The PFO 1040 is a real-time particle fallout (or deposition) monitor designed for cleanrooms and controlled environments. It detects particles in the range from 5 um to >750 um that settle onto surfaces, rather than particles that remain airborne. Its purpose is to detect and quantify surface contamination risks that might lead to yield loss in sensitive processes.

The PFO 1040 uses XCAM Scientific’s Direct Particle Detection (DPD) technology to directly image and analyse particles that settle onto a silicon imaging sensor. In simple terms, particles land on the sensor surface, where built-in illumination and high-resolution CMOS detectors capture detailed images. Advanced onboard algorithms then process these images to measure each particle’s size, shape, and type (for example, distinguishing particles from fibres). This direct-imaging method allows the system to continuously monitor and quantify surface contamination, from 5 µm to >750 µm.

The PFO 1040 automatically analyses each image capture and provides detailed, time-stamped contamination data. Its output includes particle count, size distribution, shape classification (particle or fibre), percentage area coverage, and trend information over time. Results can be viewed through XCAM Scientific’s software interface on PC via USB cable or exported for external analysis. The system also supports configurable alerts and alarms when contamination exceeds set thresholds and can generate reports compliant with various cleanliness standards including IEST-STD-CC1246E for audit and quality-control purposes.

Particle fallout monitoring measures particles that can settle onto critical surfaces, complementing airborne particle monitoring. Even in cleanroom environments, larger particles (typically ≥5 µm) quickly settle from the air onto surfaces, potentially contaminating sensitive equipment, products, or processes. By tracking these deposits in real time, facilities can identify contamination sources, evaluate cleaning effectiveness, maintain product quality, and ensure compliance with cleanliness standards, helping prevent costly defects and failures in performance.

Traditional particle monitoring protocols often rely on manual surface testing methods such as adhesive tape lifts or witness plates, which provide only periodic or delayed results. These methods are also highly demanding of lab personnels time. In contrast, the PFO 1040 uses Direct Particle Detection (DPD) to continuously and automatically image particles as they settle on a sensor surface. This delivers real-time, quantitative data on particle size, type, and distribution without manual intervention. By providing continuous digital data and automated alerts, the PFO 1040 offers faster, more reliable, and more traceable contamination monitoring than traditional manual or sample-based methods.

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific is now part of Tibidabo Scientific IndustriesStrengthening our ability to deliver world-class imaging solutions for space, scientific, and industrial applications.