Custom Solutions

Space, science and industrial applications

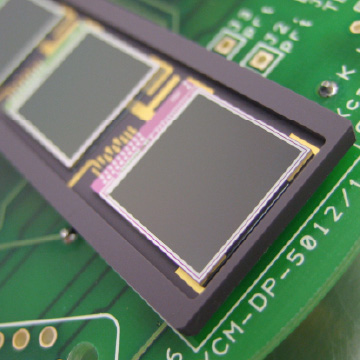

Camera Subassemblies

Components for customised systems

Space, science and industrial applications

Components for customised systems

At XCAM Scientific, we specialise in creating tailored camera systems by combining our extensive library of components and subassemblies with tailored electronics to meet specific application requirements.

While we offer a range of commonly supplied cameras, we pride ourselves on the ability to customise each system to meet unique experimental requirements. Whether you need a different detector, a modified mechanical camera head, or a specific configuration, our expert team can design and build a custom solution to fit your needs.

Our custom cameras leverage advanced imaging technologies and algorithms to deliver exceptional performance in specialised applications such as Soft X-ray detection and Resonant Inelastic X-ray Scattering.

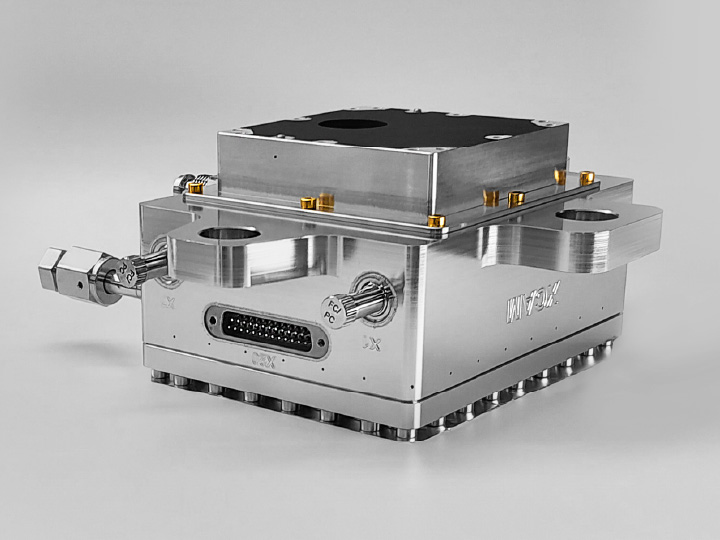

XCAM Scientific designs and manufactures bespoke camera systems tailored for demanding environments - from in-vacuum systems to space-qualified hardware. Our cameras are engineered with high-performance electronics to ensure reliable and consistent detector operation, even under extreme conditions.

Our camera systems are designed with future integration in mind, including compatibility with on-board processing boards. This ensures seamless operation within larger systems and enables faster data handling at the point of capture.

We offer a range of optional features to enhance system flexibility and functionality. From modular components to advanced interface options, our custom systems can be configured to meet specific experimental or operational needs.

XCAM Scientific’s custom cameras can enable real-time data analysis, intelligent filtering, and enhanced decision-making capabilities - particularly beneficial for autonomous or remote sensing applications.

Every successful project begins with understanding your goals. We work closely with you to understand your application, define objectives, technical requirements, and environmental constraints. By exploring the challenges and opportunities unique to your application, we establish a clear foundation for a tailored imaging solution that meets your exact needs.

Building on the consultation insights, we develop a detailed design concept for your imaging system. This includes defining the mechanical concept, the overall system architecture, evaluating component options, and identifying technical risks. The outcome is a clear, validated design approach ready for development and manufacturing.

Our engineers translate the design concept into a working system through iterative design reviews and prototype development. Using simulation, modelling, and early integration testing, we refine hardware, electronics, and software to ensure optimal performance and reliability before full manufacture.

Once the design is validated, we source and assemble high-quality components and materials to exacting standards. Every element is selected and built for performance, longevity, and compatibility with your operational environment, whether in the lab, on the production line, or in orbit.

During this phase, we assemble, integrate, and test the full imaging system. Mechanical, electronic, and software subsystems are brought together and verified to ensure seamless operation. This stage may include prototype builds, engineering models, or fully deliverable or flight-ready systems depending on the requirements of the customer and the project.

Rigorous testing ensures that the system performs as designed. We verify functionality, calibration, and performance under simulated operating conditions. For space systems, this can include environmental testing for vibration, thermal, vacuum, and radiation exposure; for ground-based systems, testing is tailored to the intended application environment.

Once the system has successfully completed all validation stages, it is delivered, fully documented, and supported by our engineering team. We provide ongoing technical assistance, performance monitoring, and, where needed, continued development for future enhancements or missions.

Cold Atom Space PAyload - A 6U CubeSat developed by a UK based consortium to demonstrate the technology of laser-cooling atoms in space.

Read MoreEMCCD camera system for the Off-plane Grating Rocket Experiment (OGRE) mission.

Read More

Space camera for precision forestry to monitor the health of trees from space.

World's first ECSS space standards compliant TVAC chamber camera designed for Optical Ground Support Equipment (OGSE) used to test space optics during qualification.

Flexible multi-detector CCD-based camera system for an X-ray Free Electron Laser (XFEL) beamline

Read More

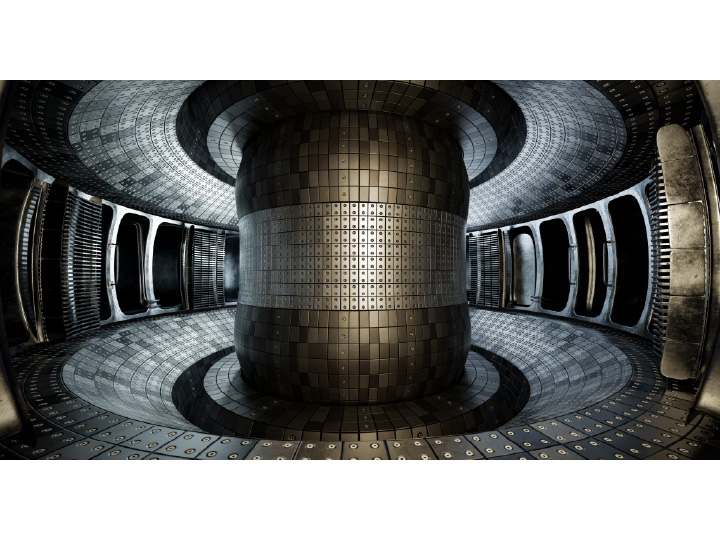

Multiple-windowed camera system for high frame rate multi-fibre optical spectroscopy. This technology was initially developed for fusion reactor diagnostics.

Single detector CCD concept for X-ray Free Electron Laser Experiment (XFEL).

Read MoreWe specialise in large area and multiple CCD/EMCCD/sCMOS cooled camera systems, designed to meet the needs of leading-edge scientific experiments. By understanding your application, we optimise the choice of CCD type and manufacture to maximise performance.

Swept Charge Devices (SCD) deliver X-ray spectroscopy and offer a low cost, large area, fast read-out alternative to 2D-imaging CCDs, for situations where spatial information is not required. Designed to operate at temperatures that can be achieved using Peltier cooling (so liquid nitrogen is not required) makes them an ideal replacement for Si(Li), PIN, and SDD devices.

We design and build advanced imaging systems for time-resolved spectroscopy, enabling the capture of rapid, dynamic processes. Our cameras are engineered for high temporal and spatial resolution, high frame rates, and low noise ensuring the delivery of reliable data for applications ranging from materials science to photonics research.

Our imaging systems for extreme ultraviolet (EUV) lithography are engineered for precision. We design in-vacuum, contamination-controlled systems that perform reliably in high-vacuum environments for 24/7 operation, supporting metrology and process development at the cutting edge of semiconductor manufacturing.

We design and supply ground support equipment (GSE) camera systems for spacecraft component and system testing, integration, and verification. Our robust, high-performance cameras are tailored to operate in simulative flight conditions, support system validation, and ensure mission readiness.

XCAM Scientific's synchrotron cameras are designed for imaging in high-and low-flux, high-radiation beamline environments. We develop systems with exceptional stability, low noise, and high dynamic range to support a wide range of beamline science and materials research applications.

XCAM Scientific’s engineering team is ready to support your mission, from early design to deployment.

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific

2 Stone Circle Road

Round Spinney Industrial Estate

Northampton, NN3 8RF, UK

XCAM Scientific is now part of Tibidabo Scientific IndustriesStrengthening our ability to deliver world-class imaging solutions for space, scientific, and industrial applications.